1. Introduction to hub bearing

Bearing, known as the cornerstone of industry, its importance is beyond doubt.

There are tens of thousands of parts in a car. Where there are rotating pairs, there are bearings. There are dozens of bearings inside the engine gearbox.

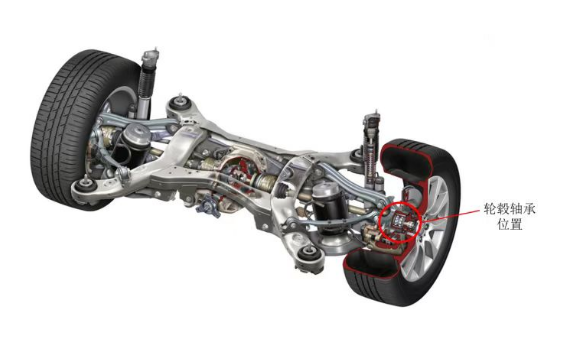

The following are hub bearings.

.jpg)

The wheel hub bearing is usually hidden tightly and cannot be easily seen.

The wheel hub bearing is a part that connects the tire (rotating part)/brake disc (rotating part) and steering knuckle (fixed part). Its main function is to reduce the friction force for the rotating pair, and also plays the role of transmitting force. It bears very large radial load (vehicle weight) and axial load (lateral force or lateral impact force of tire during steering).

2. Development history of hub bearing

Hub bearings are divided into ball bearings and tapered roller bearings.

The difference mainly lies in whether the rolling medium (roller) inside is spherical or conical in shape.

Except for vehicles with extra heavy load (engineering vehicles, large SUVs, pickup trucks, etc.), the wheel hub bearings of general passenger vehicles are ball bearings.

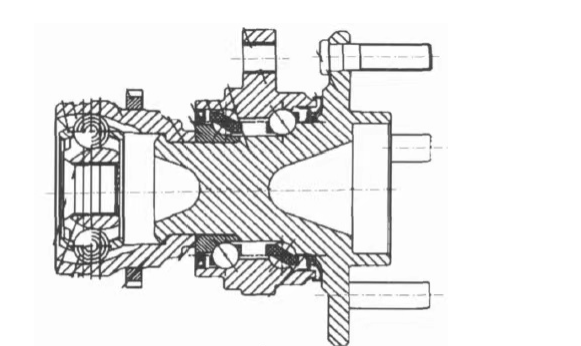

There are three kinds of bearings in the front bearing picture, namely the first generation bearing, the second generation bearing and the third generation bearing.

The structure of the first generation bearing is the simplest, mainly including an inner ring, an outer ring and a steel ball. And the cost is the lowest.

Although the first generation bearing has the advantages of simple structure and cost, it also has many disadvantages.

First of all, it is inconvenient to assemble in the car factory.

As the first generation bearing is independent of the knuckle and hub, it is necessary to press the inner ring of the bearing onto the hub and the outer ring of the bearing onto the knuckle during online assembly.

Because the assembly process is complex, the requirements for equipment and process control are high.

The second is poor performance.

Because the process cannot be accurately controlled during installation, the performance deviation of the pressed bearing is also large, and the overall performance is low.

Due to the above shortcomings of a generation of bearings, their output has declined year by year.

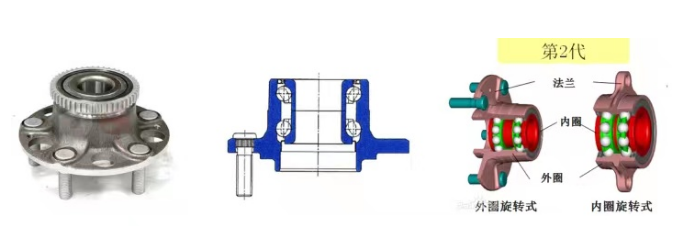

The structure of the second generation bearing is slightly more complicated, and the hub is integrated on the basis of the first generation bearing.

Compared with the first generation bearing, the process of pressing the wheel hub is omitted during assembly, but the interference fit assembly with the knuckle is also required, and the assembly accuracy is only slightly higher than that of the first generation bearing.

However, it also has the disadvantage of poor performance.

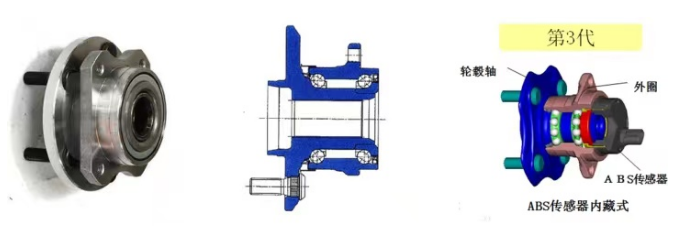

In terms of integration, the inner ring of the third generation bearing is integrated with a hub, and the outer ring is integrated with a flange connecting the knuckle, which can be connected with the knuckle through bolts. The assembly accuracy is greatly improved.

And since all dimensions are precisely controlled by the supplier, the performance is the best.

Because of these two advantages, although the cost is slightly higher, the third generation bearings are still favored by almost all mainstream car manufacturers.

3. Key points of bearing design

When designing bearings, the following points are mainly examined:

Interference and clearance design (mainly for the first and second generation bearings)

Bearing strength/stiffness

Bearing drag torque

Bearing life

Tightness

Bearing strength:

Because the bearing has to bear very large radial and axial loads, the strength is very critical. Generally, stress and strain analysis is carried out through CAE with a certain safety margin.

Bearing stiffness:

If the stiffness of the bearing is very poor, it will lead to large deformation of the flange surface connecting the bearing and the brake disc when the bearing is subjected to lateral force, which will lead to eccentric wear of the friction plate and other problems.

Bearing drag torque:

The drag moment of the bearing is the resistance when the bearing rotates. Its size affects the fuel consumption and the driving range of new energy vehicles.

Bearing life:

The bearing is maintenance free throughout the life cycle of the vehicle, so its life must be longer than that of the whole vehicle. Its life calculation has very complex calculation formula, which is also the skill of different parts suppliers.

Tightness:

It means that the seal ring prevents the external water/dust from entering the bearing, which affects the lubrication of the steel ball and ultimately affects the service life of the steel ball.

4. How to judge whether the bearing is damaged

To judge whether the bearing of the vehicle is damaged, the following two methods can be used:

Place the vehicle on the lift, rotate the wheel with force to see if the wheel is stuck, and evaluate whether the drag torque of the wheel is normal. If the steel ball is poorly lubricated or out of round, it will lead to seizure or increase of drag torque.

Pay attention to whether there is abnormal noise in the wheel direction during normal driving. If the steel ball is not lubricated well, the first problem is abnormal noise. If there is no abnormal noise, there is generally no problem.

In addition, since most of the current wheel speed sensor signal sources (magnetic poles or coils) are integrated in the bearings, if the wheel speed signal has a problem, the instrument cluster will report a fault code, and the ABS fault lamp as shown in the following figure will light up.

Therefore, if the ABS fault light is always on, the magnetic pole of the bearing may be damaged.

.png)

|